Tech

Screw Gauge: Formula, Working Principle & Uses

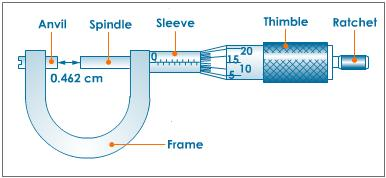

Screw gauge is a measuring device that is used to measure the thickness of a thin sheet or the diameter or the radius of a wire. The parameter to be measured using the 2 scales on the screw gauge i.e. the Pitch scale and the circular scale. Screw gauge is used to measure the outer dimension of an object. It contains a U-shaped frame and a spindle that is attached to the thimble.

What is a Micrometer Screw Gauge?

A micrometer Screw Gauge is a measuring instrument that is used to measure the outer dimensions of a given object with precision. A screw gauge consists of 2 scales – a pitch scale and a circular scale – which account for calculating the dimension correctly upto 2 decimal points. Micrometer Screw gauges are more accurate as compared to vernier calipers.

- Pitch Scale: This is the main scale that measures the distance moved by the spindle per revolution in millimeters. The scale is marked by vertical lines on the barrel / sleeve of the instrument [refer figure for better understanding].

- Circular Scale: This is the secondary scale that is marked horizontally on the thimble. One revolution of the circular scale is equivalent to half a millimeter of screw displacement.

Screw Gauge: Formula

Every screw gauge has 2 common parameter – a pitch and the least count:

- Pitch: Pitch of the screw gauge is the distance moved by the spindle per revolution and is calculated by:

Pitch = Distance moved by the screw / Number of rotations

- Least count: Least count of the screw gauge is defined as the distance moved by the screw when it turned through 1 division of the head scale and is calculated by:

Least Count = Pitch of the screw gauge / Total number of divisions on the circular scale

- Screw Gauge Reading = It is the final measurement of the dimension of the object that is being measured.

Total reading = Pitch scale reading + (Circular Scale Reading * Least Count)

Screw Gauge: Working Principle

The working principle of the Screw Gauge is based on the movement of principle. It converts the smaller distances into larger distances by measuring the rotations of the screw on the pitch scale. The final dimension is calculated by adding the measurements taken from both the scales.

Differential Screw is one of the important components of the ordinary screw gauge as it allows calculation of smaller dimensions with ease. When the screw is rotated 360 degrees, it covers a small axial distance on the barrel thus allowing to calculate the dimension with better accuracy.

- The distance traveled by the screw in one complete rotation is known as the lead of the screw.

- The Digital Screw gauges display the dimension on the LCD screen attached to the fram; however, the digital screw gauges are the least accurate among others.

Measurement using Screw Gauge

To measure the dimension of any object using screw gauge, candidates can follow these simple steps:

- Check for any prevalent zero errors in the screw gauge.

- Note down the pitch and the least count of the screw gauge provided.

- Place the object in between the anvil and the spindle and rotate the thimble until you hear a click.

- Now, remove the object with care and note down the readings.

- Make sure to enter the readings of both the scales into separate columns to avoid any errors.

- Now, calculate the required dimension using the formula of the measurement of micrometer screw gauge.

- Take at least 3 readings similarly of the same object.

- The final dimension can be calculated by taking the average of the number of readings taken.

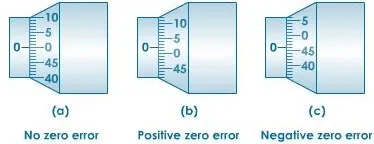

Zero Error in Screw Gauge

When the Spindle of the screw gauge has been tightened completely without placing any object in between and if the zeroes of both the scale do not match, it is known as the zero error of the micrometer screw gauge. Zero errors are of 2 types – positive zero error and negative zero error.

- Positive zero error – When the zero of the circular scale is below the zero mark of the pitch scale, it is known as the positive error.

- Negative zero error – When the zero of the circular scale is above the zero mark of the pitch scale, it is known as the negative zero error.

Figure: Zero error in Screw Gauge

How to correct Zero error?

Zero errors can be corrected either by adding or subtracting them from the final measurement.

For positive zero error, the number of lines zero below the pitch scale is multiplied by the least count of the screw gauge and then this number is subtracted from the final reading of the micrometer screw gauge.

While, in case of negative zero error, the number of lines above the zero mark of the pitch scale are to be multiplied by the least count and then added to the final reading of the micrometer screw gauge.

Uses of Screw Gauge

Screw gauge is a measure device that is used to measure the outer dimension with an accuracy of 0.01 mm. It is mostly used in industries to:

- Measure the diameter of the wire.

- Measure the outer diameter of cylindrical objects.

- Measure the thickness of the sheet metals.

- Uniformity in thickness of the sheet metals.

-

Blog1 year ago

MyCSULB: Login to CSULB Student and Employee Portal – MyCSULB 2023

-

Android App3 years ago

Cqatest App What is It

-

Android1 year ago

What Is content://com.android.browser.home/ All About in 2023? Set Up content com android browser home

-

Software2 years ago

A Guide For Better Cybersecurity & Data Protection For Your Devices

-

Latest News2 years ago

Soap2day Similar Sites And Alternatives To Watch Free Movies

-

Android2 years ago

What is OMACP And How To Remove It? Easy Guide OMACP 2022

-

Android3 years ago

What is org.codeaurora.snapcam?

-

Business2 years ago

Know Your Business (KYB) Process – Critical Component For Partnerships