Industrial

What is the Importance of Kvar Correction for Reducing Maintenance Costs in Industrial Settings?

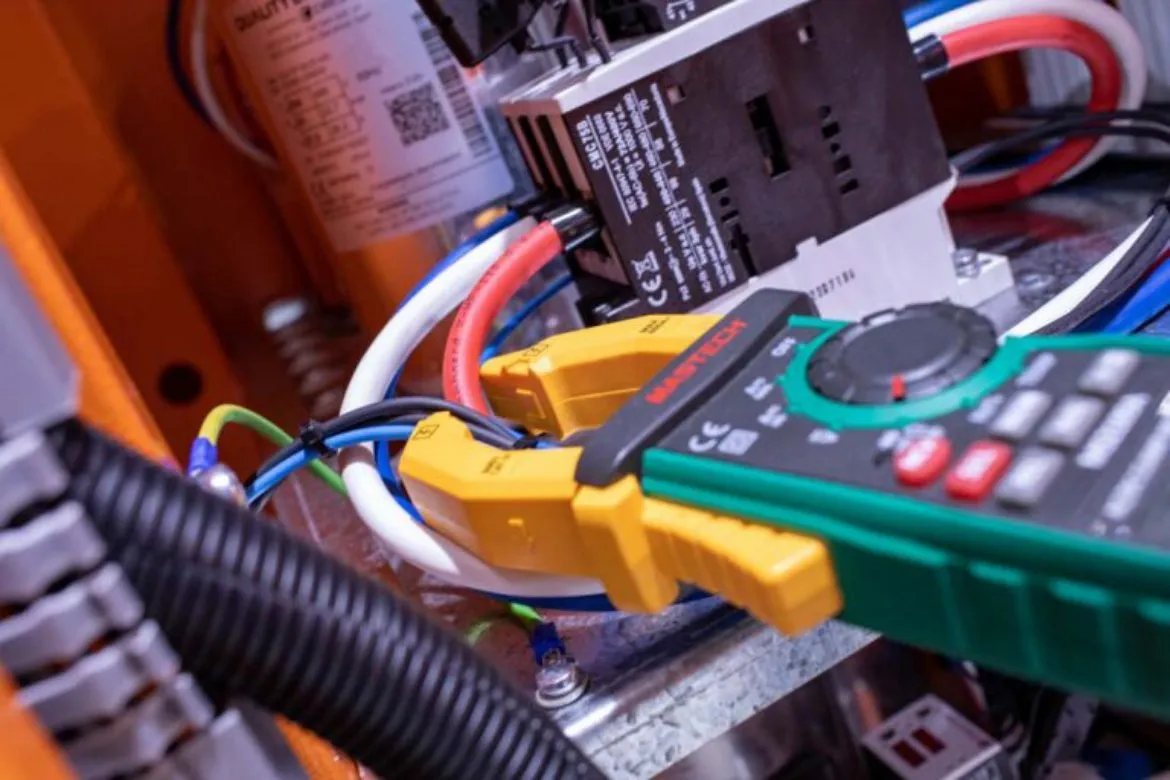

The low power factor in industrial plants is most commonly corrected by adding power capacitors to the plant distribution system.

Capacitors can help correct lagging PF by increasing conductor and transformer current load up to the motor, improving motor performance. They can also improve overall system voltage by reducing voltage drops caused by long feeders and field pumping operations.

Reduced Maintenance Costs

In industrial settings, kVAr correction is critical to ensure the continued performance and safety of machinery. Power factor correction reduces the amount of energy needed to run equipment and improves its lifespan. It also helps to reduce electrical costs and lower a company’s carbon footprint, making it an important investment for businesses.

To correct a low power factor, kVAR correction equipment is used in conjunction with power distribution systems such as capacitor banks and synchronous condensers. These devices reduce reactive losses (inductive or capacitive) to bring a poor power factor back to a more favorable level. Check this link to learn more about reducing kVAr.

Several factors determine whether installing a power factor correction system in an industrial environment makes sense. These include power factor penalties imposed by the utility, reduced maintenance costs, and improved equipment performance.

It is also important to note that if a business is billed for a power factor lower than the actual one, a kVAr correction system could be worth it. It is a situation that is not common in residential environments but can be a problem for businesses that have larger three-phase motors in operation.

For these reasons, it is important to consult a licensed and qualified contractor for all your commercial power factor correction needs. In addition to being able to help you avoid costly penalties from the utility, these technicians can help you reduce your energy bills and make your business more eco-friendly.

Reduced Energy Consumption

Adding capacitors to the facility’s electrical distribution system can correct the low power factor. Capacitors can be used in various applications, and they can be installed as part of an automatic power factor correction unit or as fixed capacitors at individual loads.

Capacitors reduce kVAr demand by introducing reactive current sources into the circuit to counteract the energy absorbed by loads. It improves a circuit’s power phase and helps avoid electric utility penalties.

A high power factor ratio can reduce the amount of energy consumed in a circuit, which is an important consideration for both consumers and utilities. It can lead to lower bills and improved equipment performance and durability.

It is also important to consider the amount of reactive power in a circuit, as this can have an impact on energy consumption. Reactive power includes voltage sags, harmonic distortion and power loss from long conductors. An engineer can assist you in sizing the correct equipment for your application.

Increased Equipment Life

A poor power factor can also create an unnecessary load on the electric grid and increase your facility’s carbon footprint. Reactive power is a component of electricity that does not do any work and is essentially wasteful, but it can be reduced using power factor correction.

Your monthly power bill directly reflects the amount of reactive power drawn from the electrical grid. Improving your power factor can reduce these costs and make your company more efficient. It can also help to improve your facility’s public image as an environmentally responsible business.

Correcting your power factor is easy and can be accomplished with various equipment. Some of the most common types of equipment include capacitor banks and synchronous condensers.

When a power factor is corrected, the equipment’s efficiency will increase, prolonging its life. It will also prevent motor failure and other damage to your equipment.

If you have a large equipment fleet, the savings from power factor correction will quickly add up. Installing power factor correction equipment can reduce operating costs by avoiding expensive maintenance and repair bills.

Increased Capacity

In industrial settings, a lower power factor is a major issue that causes power loss and voltage drop in equipment and motors. Installing kVAr correction equipment can significantly reduce these costs, as well as improve the overall efficiency of your facility’s electrical system.

A poor power factor will result in higher current flowing through your lines, causing more conductor losses and a lower voltage at the load. It can cause equipment to overheat or malfunction, which can ultimately lead to costly repair bills.

There are many ways to correct a low power factor. However, one of the most effective methods is the installation of power factor correction capacitors in your system.

These devices work by reducing the amount of reactive energy in your circuits. They also improve the power quality of your circuits and reduce the source current needed to run your equipment.

Capacitors can be installed at the load in several different ways. However, typically the best approach is to connect larger capacitor banks to your electrical distribution bus or to use automatic systems at the incoming service in conjunction with fixed capacitors at distributed loads.

Another problem that some people face is the introduction of modern loads containing uncontrolled rectifiers (such as variable speed drives and computer power supplies). These load types draw harmonic currents from your supply, which can reshape both the site current and voltage waveforms.

-

Blog1 year ago

MyCSULB: Login to CSULB Student and Employee Portal – MyCSULB 2023

-

Android App3 years ago

Cqatest App What is It

-

Android1 year ago

What Is content://com.android.browser.home/ All About in 2023? Set Up content com android browser home

-

Software2 years ago

A Guide For Better Cybersecurity & Data Protection For Your Devices

-

Latest News2 years ago

Soap2day Similar Sites And Alternatives To Watch Free Movies

-

Android2 years ago

What is OMACP And How To Remove It? Easy Guide OMACP 2022

-

Android3 years ago

What is org.codeaurora.snapcam?

-

Business2 years ago

Know Your Business (KYB) Process – Critical Component For Partnerships