Blog

A Comprehensive Guide to Prototyping Electronic Hardware Products

Developing a new consumer product involves rigorous testing and prototyping before it reaches the market as a final product. This guide aims to provide insights into the essential aspects of prototyping for electronic hardware products, highlighting key stages and requirements. The journey of bringing an electronic product to the market encompasses various prototyping phases, with each iteration contributing to refining the design. Despite advanced computer-aided design capabilities, multiple prototypes are often necessary before achieving a production-ready version for mass manufacturing.

Prototyping as a Learning Process

The heart of product prototyping lies in the pursuit of knowledge. Each prototype iteration should offer valuable insights. A prudent approach is to begin with a simple and cost-effective prototype method, progressively advancing towards a production-quality model. During the initial stages, it’s beneficial to categorize the product into distinct prototype types, each serving a specific purpose.

The Importance of Proof-of-Concept Prototypes

In the realm of electronic prototyping, the proof-of-concept (POC) prototype holds significant importance. It serves as the foundational representation of the product, albeit not resembling the final design. The primary objective of the POC prototype is to validate the core concept of the product while keeping costs minimal.

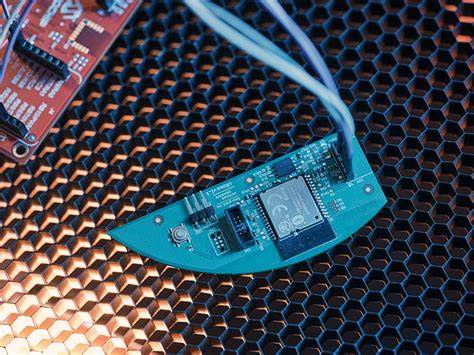

For many electronic hardware products, POC electronics prototyping leverages development kits like Raspberry Pi or Arduino, which typically involve microcontrollers or microprocessors. This prototype type is particularly useful when fundamental questions about problem-solving capabilities arise.

Look-Like Prototypes for Aesthetics and Feel

Look-Like Prototypes (LLP) emphasize the visual and tactile aspects of a product, independent of its functionality. Often referred to as work-like prototypes, LLPs concentrate on perfecting aesthetics through methods such as clay modeling, foam shaping, 3D printing, CNC machining, and injection molding. Separating the visual appeal from functionality is crucial in electronic prototype manufacturing.

Traditional methods like clay and foam remain valuable in the early stages, enabling swift and cost-effective concept transformation into tangible forms. These techniques aid in experimenting with the product’s shape, size, and ergonomics. When initiating electronic prototype manufacturing, beginning with clay models can streamline the transition to more advanced techniques like 3D printing.

Prototyping the Electronics

Effective prototyping involves posing well-defined questions that each iteration must address. To assess the product’s viability and problem-solving potential, starting with an early work-like prototype based on platforms like Raspberry Pi or Arduino is recommended. In cases where fundamental functionality questions are fewer, progression to designing a customized Printed Circuit Board (PCB) becomes appropriate.

The PCB prototyping process entails two key steps:

Fabricating the bare PCB: Laminating woven glass epoxy cores acts as insulation between conductive layers, providing physical support to the board.

Soldering components: After laminating, the process involves plotting the layout design for each conductive copper layer on film, exposing them to UV light, and then chemically treating to remove unexposed layers, leaving the desired traces.

Subsequent processes include drilling vias for signal connections, electroplating copper surfaces, placing and soldering electronic components using robotic equipment, and finalizing the connections through a reflow oven.

Conclusion: Navigating the Prototype Journey This guide underscores the intricate and iterative nature of electronics prototyping. It’s a process that demands patience and thoroughness, with each prototype contributing to refining the final design. Rushing into advanced prototyping techniques is discouraged until comprehensive insights are gained from earlier, less complex iterations. The ultimate objective is to create a single, well-informed prototype before embarking on full-scale production, ensuring optimal results for the product’s success.

-

Blog1 year ago

MyCSULB: Login to CSULB Student and Employee Portal – MyCSULB 2023

-

Android App3 years ago

Cqatest App What is It

-

Android1 year ago

What Is content://com.android.browser.home/ All About in 2023? Set Up content com android browser home

-

Software2 years ago

A Guide For Better Cybersecurity & Data Protection For Your Devices

-

Latest News2 years ago

Soap2day Similar Sites And Alternatives To Watch Free Movies

-

Android2 years ago

What is OMACP And How To Remove It? Easy Guide OMACP 2022

-

Android3 years ago

What is org.codeaurora.snapcam?

-

Business2 years ago

Know Your Business (KYB) Process – Critical Component For Partnerships